Managing a fleet of construction machinery requires tough decisions. One of the most critical choices owners and fleet managers face is determining when to fix a machine and when to let it go. Keeping an aging piece of equipment might seem cheaper in the short term, but mounting repair bills can quickly eat into profits. On the other hand, buying new machinery is a massive capital expense that needs strong justification.

Making the right call between repairing and replacing is essential for maintaining a healthy bottom line. This guide explores the key factors you should weigh to manage your fleet effectively.

Table of Contents

ToggleAnalyze the Total Cost of Ownership

The first step in this decision process is looking at the hard numbers. Every machine has a lifecycle cost that goes beyond the purchase price. You need to track the Total Cost of Ownership (TCO) for each asset. TCO includes the initial purchase price, fuel consumption, insurance, taxes, and ongoing maintenance.

As equipment ages, maintenance costs naturally rise. You should track these expenses carefully. A common rule of thumb is the “50% rule.” If the cost of a necessary repair exceeds 50% of the machine’s current market value, replacement is often the smarter financial move. Pouring money into an asset that is depreciating rapidly rarely yields a good return on investment.

Consider Equipment Downtime and Reliability

The cost of a breakdown is never just the invoice for parts and labor. The real cost lies in lost productivity. When a critical excavator or loader goes down, it can halt an entire project. This leads to missed deadlines, idle crews, and potential penalties for contract delays.

Evaluate the reliability of your current equipment. If a machine has become unpredictable, it poses a risk to your operations. Frequent minor breakdowns are a warning sign. Even if each repair is cheap, the cumulative downtime is expensive. Newer machines offer better reliability and come with warranties that protect you from unexpected costs. If your current equipment spends more time in the shop than on the job site, it is time to consider an upgrade.

Safety and Technology Upgrades

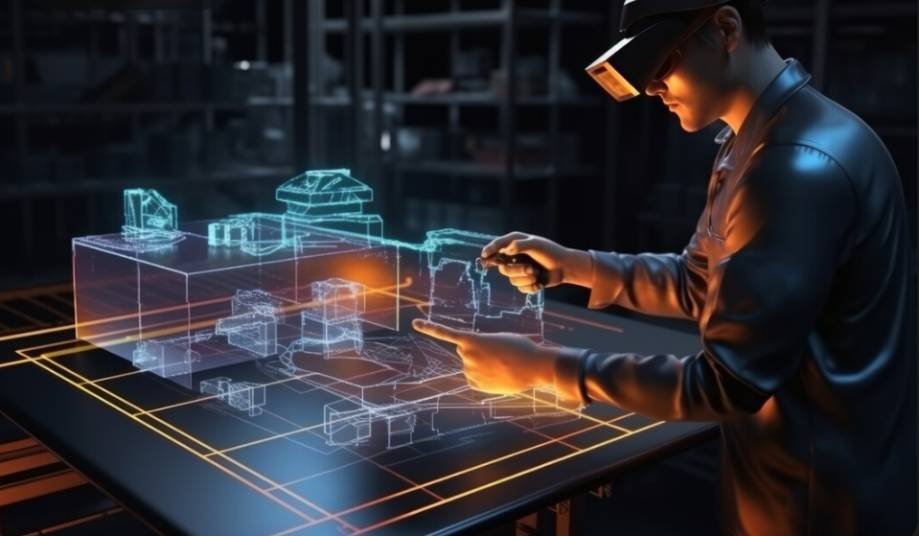

Construction technology moves fast. Newer models are not just shiny updates; they often feature significant advancements in safety and efficiency. Modern equipment comes with better blind-spot monitoring, improved stability controls, and more ergonomic operator cabins. These features reduce the risk of accidents and operator fatigue.

Beyond safety, consider efficiency. Newer engines often consume less fuel and produce fewer emissions. They might have telematics systems that allow for better fleet tracking and preventive maintenance scheduling. If your older machines are guzzling fuel or lack modern safety features, the operational savings from a new machine could offset the monthly payments. Staying updated with technology trends can shield you at a competitive disadvantage.

Availability of Parts and Support

As machines get older, finding replacement parts becomes harder. Manufacturers eventually stop producing parts for obsolete models. This scarcity leads to longer lead times and higher prices for components. You might find yourself searching scrap yards or waiting weeks for a custom part, leaving your machine useless in the meantime.

Consider your access to professional support. If you rely on external providers for maintenance, ensure they can still service your specific model. For instance, if you operate in Utah and struggle to find reliable support for an older model, you might need to seek out specialized heavy equipment repair in Salt Lake City to keep it running. However, if finding a technician or the right parts becomes a constant struggle, upgrading to a current model ensures you have access to readily available parts and dealer support.

Depreciation and Resale Value

Timing is everything when selling used equipment. Every machine reaches a tipping point where its resale value plummets. Selling a machine while it still has some life left allows you to recoup capital to fund its replacement. If you wait until the machine is completely broken down, you might only get scrap value.

Monitor the used equipment market. Knowing what your assets are worth helps you time your exit strategy. If the market for used bulldozers is high, it might be the perfect time to sell an aging unit and upgrade, even if the old one is still running okay.

Making the Final Decision

Deciding to repair or replace is rarely black and white. It requires balancing financial data with operational realities.

Repair if:

- The repair cost is low relative to the machine’s value.

- The machine has been reliable and the breakdown is an isolated incident.

- Parts are easy to find and downtime will be minimal.

- The equipment still meets current safety and emission standards.

Replace if:

- Repair costs are approaching 50% of the machine’s value.

- The equipment is unreliable and causes frequent project delays.

- Newer models offer significant fuel savings or safety upgrades.

- Parts are becoming obsolete or difficult to source.

By keeping detailed records and regularly reviewing your fleet’s performance, you can make informed choices that keep your projects running smoothly and your budget in check.